Success Stories

Success stories. Your success is our passion.

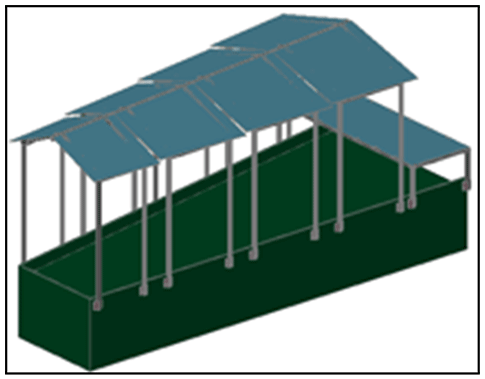

Bottling Plant Dust Covers

Overview

Dust covers were designed and built over bottling conveyors to keep the falling debris out of the bottles.

Problem/Application

This company needed a cost-effective, yet a sturdy solution to not only keep falling debris out of the bottles but also to design in a way that it was easy for the operators to clean.

Solution

Faztek played a crucial role in the design of a set of overhead dust covers spanning 4 bottling conveyors. These conveyors consisted of turns around corners as well as up to overhead sections. They also went under catwalks and were modified to go around ductwork and conduit lines. Strong, but lightweight 1.5” x 1.5” T-Slotted aluminum extrusion profiles and Lexan/Polycarbonate panels accounted for the majority of the standard guarding package offered below, along with joining plates, corner brackets, & pivot hinges to hold it all together securely. Corner brackets were used to provide adjustability when bolting to the existing conveyors.

Conclusion

After installation, it was apparent the design of these overhead dust covers provided a perfect solution to keep the bottles free of dust during operation. These guards also offered a user-friendly method of cleaning to provide an aesthetically pleasing look. Strong, sturdy, modular, and cost-effective, these units will provide years of maintenance-free performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications.

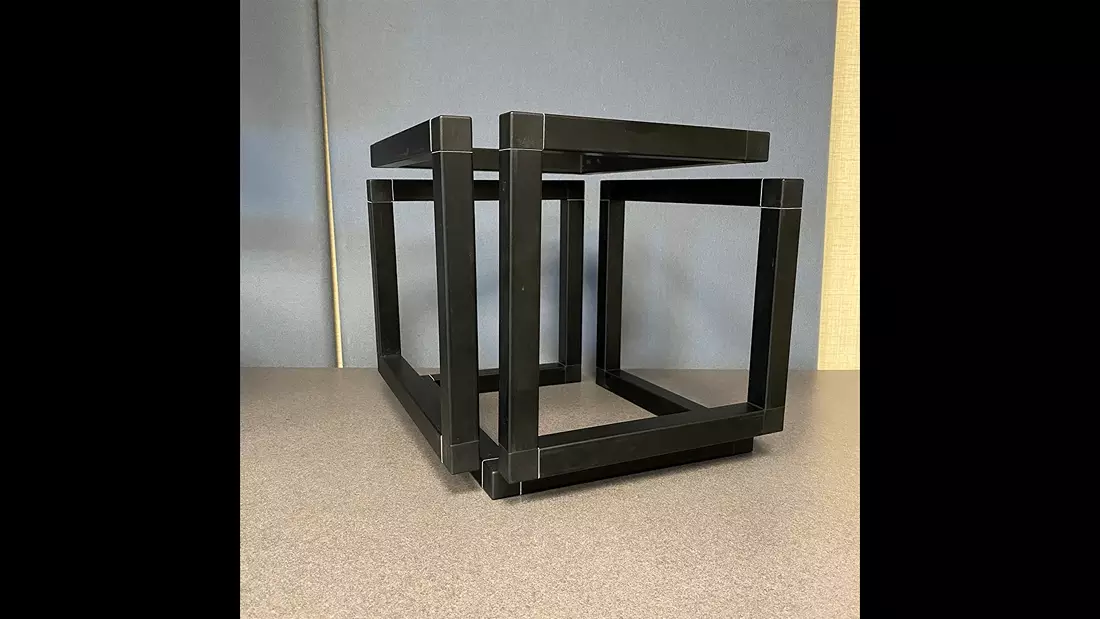

CNC Router Base

Overview

In order to accurately cut and machine panels for their customers, Faztek utilizes a programmable CNC panel router. A machine base, sold separately, was required to support the router before it could be operated properly.

Problem/Application

Faztek needed a cost-effective, yet sturdy machine base for this CNC router. Vibration and movement would be generated during operation, so the base must be able to handle these issues in addition to the weight of the router and panels being machined.

Solution

Faztek engineered a heavy-duty machine base, custom-designed for a perfect fit. Strong 3” x 3” T-Slotted aluminum extrusion profiles account for the majority of the base, along with joining plates to hold it together securely. Heavy-duty floor mount base plates were used to provide a secure seat and could also be fastened to the floor if required.

Conclusion

After installation and a quick test run, it was apparent the design of this machine base provided a perfect platform for this CNC router. Strong, sturdy, modular and cost-effective, this base will provide years of maintenance-free performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications. In this specific application, the base can easily be lowered or raised if so desired.

DIY Garage Work System

I approached Faztek to help me with what was initially a small project. I couldn’t find a tool cabinet that would maximize the use of the space in my workshop. I also wanted the flexibility to customize the solution to meet my exact needs. Using aluminum extrusion looked like a great place to start but I knew I’d need some help.

So I reached out to the Faztek Inside Sales Team and started working with the fantastic Jamie Howard to come up with an initial design. After receiving a draft, and then making a few modifications, I felt confident in placing an order. We came up with a design that exactly fits the space but also used a set of standard-length pieces. This allowed me to adapt the design once I started putting it all together.

When I received my order I couldn’t have been more thrilled with my purchase. Building the frame of my new cabinet took less than thirty minutes!

A couple of weeks later, with the rest of the cabinet built, I knew I had made the right decision! My completed tool cabinet exceeded all my expectations!

With my first cabinet built, I soon realized the full potential of what Faztek had to offer. I quickly placed an order for the parts for a second tool cabinet, and let my mind wander on what my next build would entail.

Over the course of a year, I built two large tool cabinets, a small tool cabinet, a miter saw station, a router table, a CNC router cabinet, a 3D Printer cabinet, and a large assembly table. All of these are built on the same modular design that we came up with, which has allowed me to maximize the use of pieces as I tweaked my design.

My workshop is now transformed into an exceptionally well-organized space, with every square inch of space utilized, thanks to my modular Faztek solution.

Ben Vincent

@dusty.tools

Dog Trailer

It began with a vision to create the “Ultimate Canine Recreational Unit”. I needed to find an enclosure that would be durable and be able to handle two hundred pounds of dog. I spoke to many manufacturers and came across Daniel Kline and the staff of Faztek. I put them through the mill with my quest for the perfect enclosure and after much discussion on design, the final product was created.

The kit was received, and I immediately went to work building the “Ultimate Canine Recreational Unit”. It went together effortlessly and the final product was incredible. The trailer and Faztek enclosure mating looked incredibly professional and polished.

I would like to thank Daniel Kline and the Faztek staff for their help in creating such an amazing piece of art. When the pups and I are riding around town, the comments are nothing but positive and hilarious. It turns heads like a Lamborghini driving down a crowded street.

Edward Bartus

Kissable Creatures

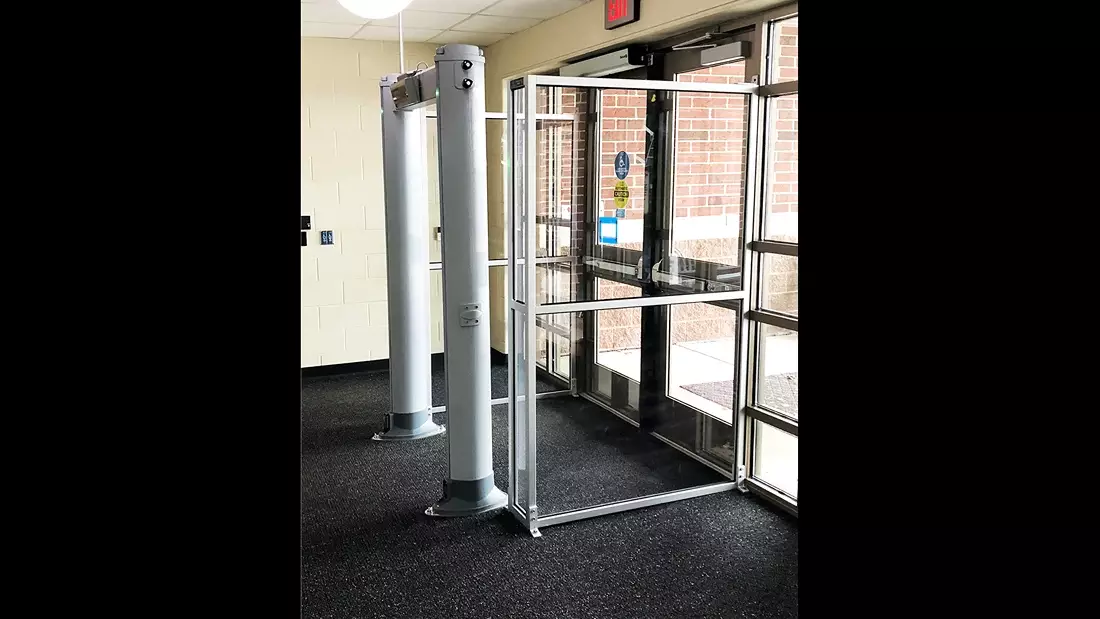

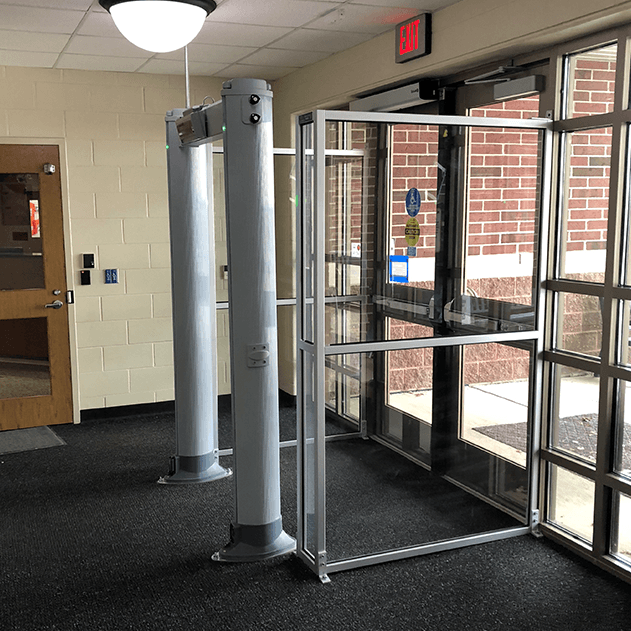

Entry Shield

I walked into Faztek with an idea in mind to help keep children in the schools safe. I sat down with Latricia Banuelos and she helped me put my idea into a design. I purchased the first one and realized we had some changes to make. Latricia worked with me the whole way through the process and never hesitated on any idea changes I had. Even the design team and the shop floor are nice and friendly and care about each and every customer. My design is now selling in schools and anytime I need more or help with new ideas Latricia is always available to help me. I would recommend Faztek to anyone who has an innovative idea they want to make a reality.

Justin Kuhn

Entry Shield

Fluid Catch Basin

Overview

A modular unit was needed to circulate and retain fluid when testing nozzles on industrial sprayers.

Problem/Application

A cart was needed to house these components in a central location allowing for easy movement and fast clean up.

Solution

Faztek designers worked closely with the customer to understand the entire scope of the project. With that, Faztek designed a cart with a cabinet built into it. The cabinet was built to house a water pump and water tank that a stainless steel tank/sink would drain into the pump. The water pump pumps fluid to nozzles on the top rail of the Faztek cabinet to test industrial sprayers.

Conclusion

After the assembly and installation of all the components, this fluid catch basin is complete and ready for use. The unit was tested and was proven to be a time-saver for both testing and clean up, as well as a cost-saver due to the capture of the fluid used in testing.

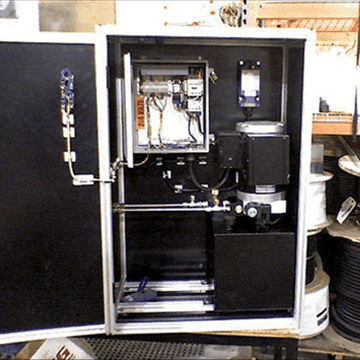

Hydraulic Power Unit Enclosure

Overview

Faztek’s T-slotted aluminum framing system was put to the test in this custom hydraulic power unit enclosure project. Using Faztek’s free design service, our Distributor was able to present a custom, cost-effective solution to a valued customer.

Problem/Application

An enclosure was needed to house an electrical control box, hydraulic power unit, and a radio remote control. In addition to housing these components, keeping the system aesthetically pleasing and protecting it from the surrounding environment was also a top priority.

Solution

Faztek designed a custom hydraulic power unit enclosure using 1” x 1” T-Slotted aluminum extrusions and 3/16” black ABS plastic panels. Adjustable rails inside create mounting options for various components. Hinges along with a chrome locking door handle complete the project and allow access into the box. This entire unit was delivered in a kit form, allowing our Distributor to assemble the enclosure and install the necessary components. Faztek also offers a complete assembly service to save you time!

Conclusion

After assembly and installation of components, this hydraulic power unit enclosure is complete and ready for use.

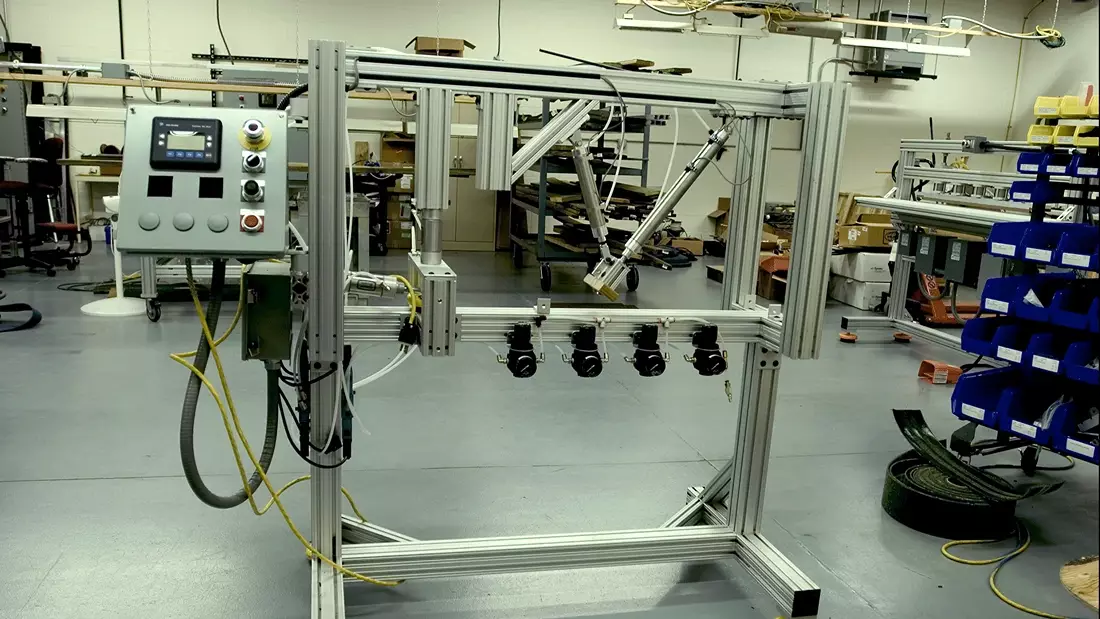

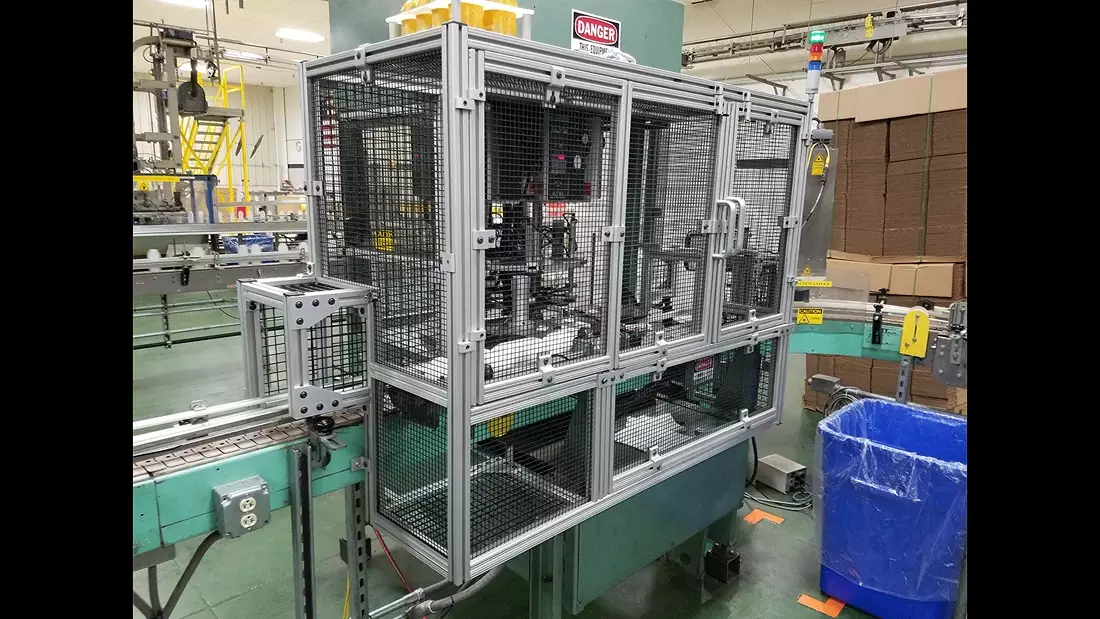

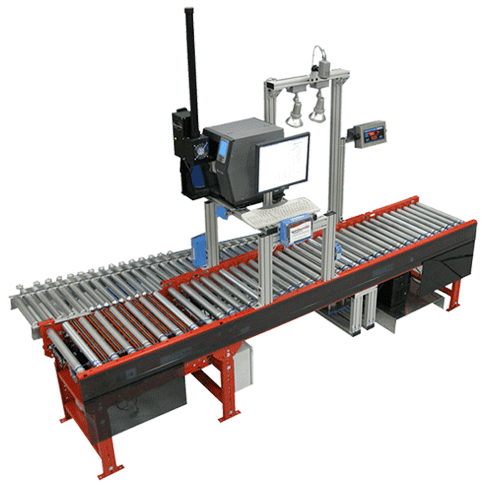

Labeling Automation System

Overview

X-Press Pal (TM) is a print and apply labeling automation system. It is designed to easily integrate with an existing pick, pack, and ship lines to eliminate the time and labor associated with manual manifesting, labeling and shipping operations.

Problem/Application

This company needed a cost-effective, yet sturdy frame to complete the design of this machine. They were looking for more automation to offer greater time savings.

Solution

Faztek worked together on the design of this machine. Strong 1.5” x 1.5” and 1.5” x 3” T-Slotted Aluminum Extrusion profiles accounted for most of the standard automation package offered below, along with joining plates, corner gussets, and anchor fasteners to hold it together securely. Heavy-duty floor mounts were used to provide a secure seat on the conveyor. This unit also includes an in-line scale, print and apply applicator, bar code scanners conveyor, and controls to automate labeling and manifesting at up to 14 cartons per minute.

Conclusion

After installation and a quick test run, it was apparent the design of this machine provided a perfect platform for the shipping industry. After the addition of the X-Press PAL (TM), they eliminated time with manual manifesting, labeling, and shipping operations. Strong, sturdy, modular, and cost-effective, these units will provide years of low maintenance performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications. ROI of 6 to 9 months!

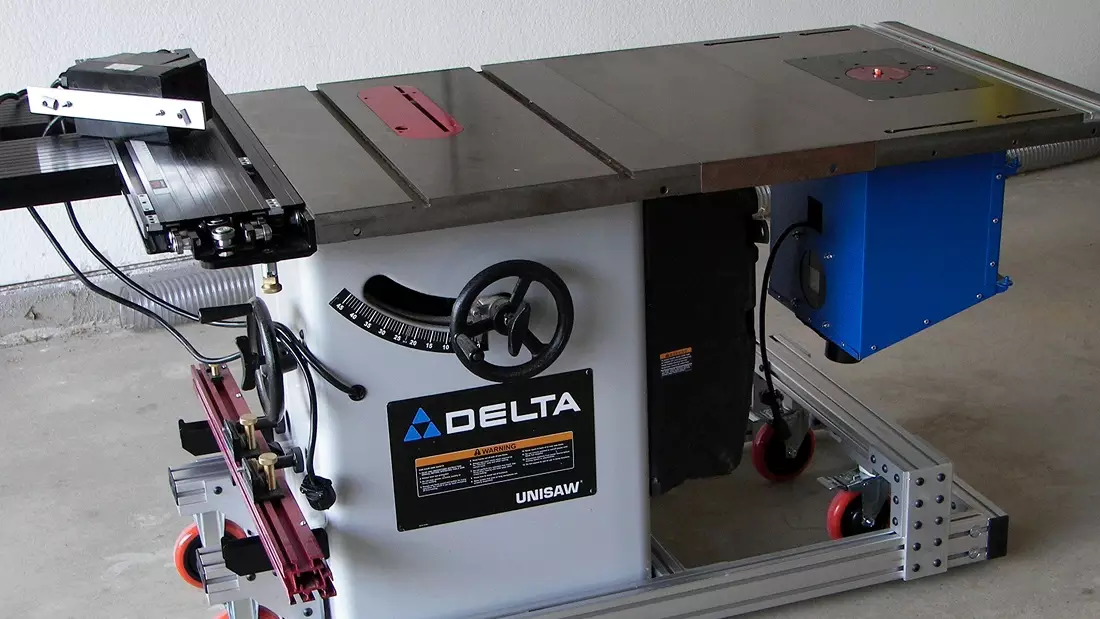

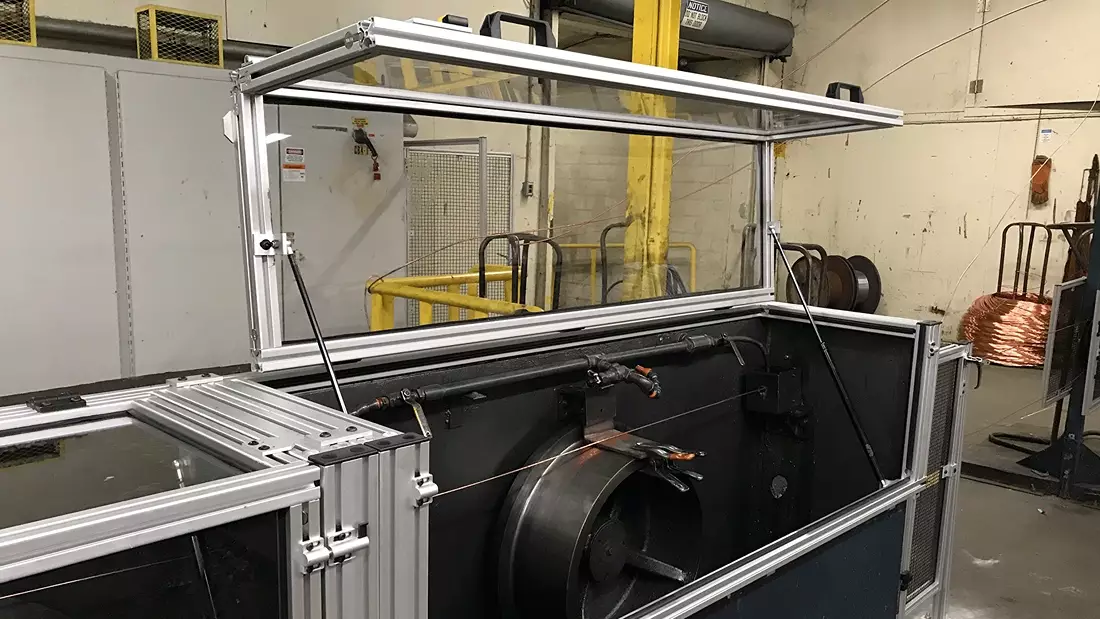

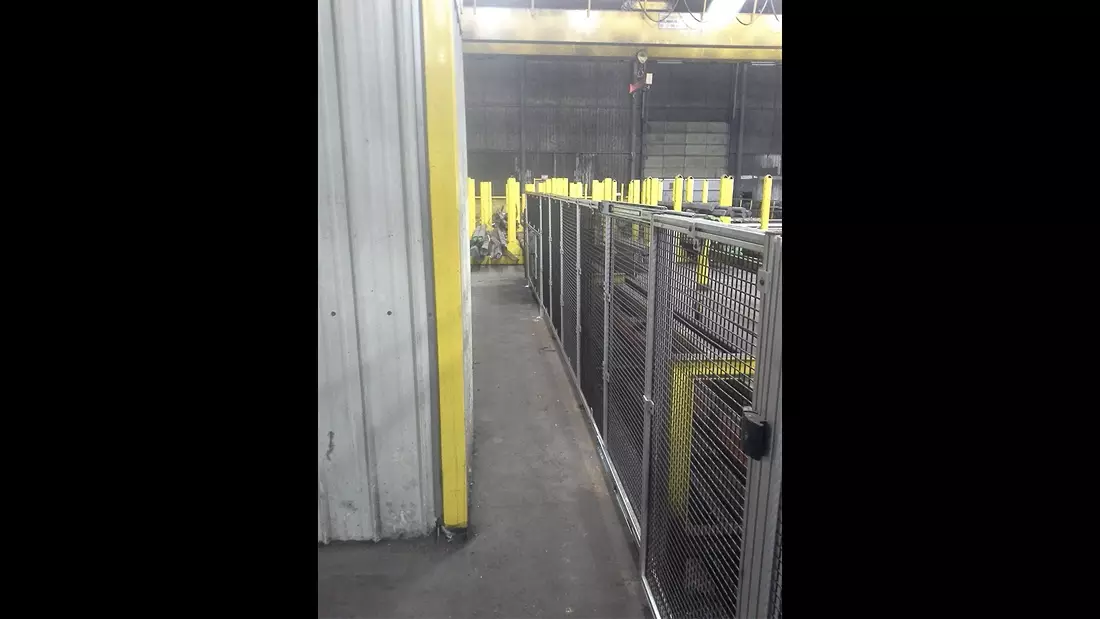

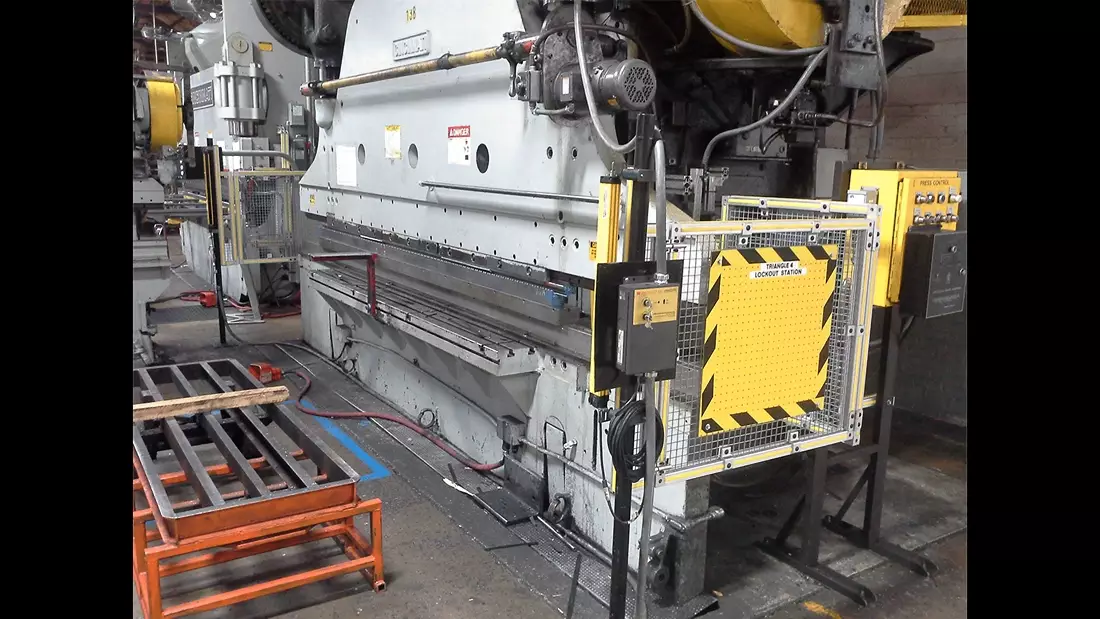

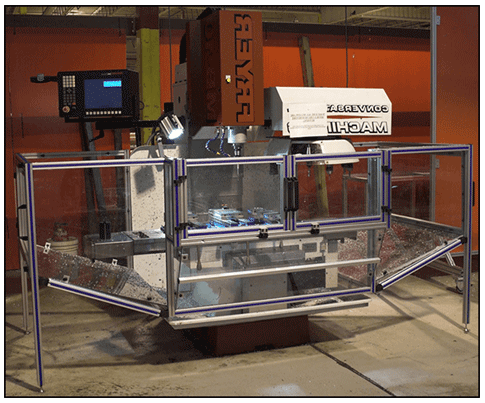

Machine Tool Guarding

Overview

Machine Tool Companies produce standard machines for the industrial market. A machine base and safety guard, sold separately, was an option they were looking to offer in order to satisfy their customer’s requirements.

Problem/Application

These companies needed a cost-effective, yet sturdy frame to complete machines. Potential safety issues, as well as chip and coolant containment, were a factor.

Solution

Faztek played a crucial role in the design of seamless integration into both machines. Strong 3” x 3” T-Slotted aluminum extrusion profiles accounted for most of the standard automation package offered below to the left, along with joining plates to hold it together securely. Heavy-duty floor mount base plates with height adjustment for uneven floors were used to provide a secure seat and could also be fastened to the floor if necessary. The machine guard to the right consisted of our most popular 1.5” x 1.5” Ultra-lite profile, along with all the t-slot components and polycarbonate panels needed to complete this unit. Leveling feet were also used for proper height adjustment for uneven floors on this machine guarding unit.

Conclusion

After installation and a quick test run, it was apparent the design of this machine base provided a perfect platform for the Robodrill. After the addition of the Fryer machine guard, operator safety was improved while saving time and money through coolant containment and fast cleanup. Strong, sturdy, modular and cost-effective, these units will provide years of maintenance-free performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications.

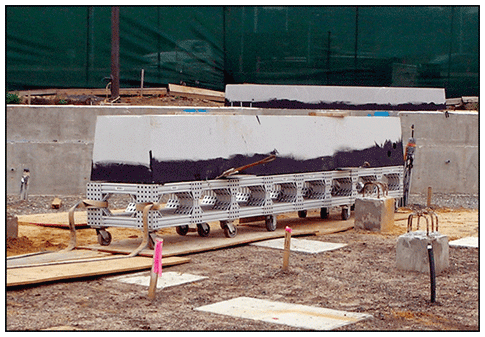

Material Handling Cart

Overview

Faztek is proud to have played a role in the construction of the Pentagon Memorial, built in remembrance of the lives lost at the Pentagon on September 11, 2001. A unique material handling solution was designed to assist construction workers involved with the project.

Problem/Application

Balfour Beatty Construction employees needed an efficient and cost-effective method of moving 184 precast memorial basins measuring 15.5’ x 2.0’ and weighing 7,000 lbs each. Ground conditions and concrete footings posed a challenge, preventing the use of traditional machinery to position the basins.

Solution

Faztek designed a heavy-duty material cart, capable of transporting these basins around the construction site safely and efficiently. Shown here is the cart being used on site. Due to the large size of this project, the cart was sub-assembled in two separate sections to allow for safe shipping. After receiving the cart, Balfour Beatty Construction simply attached the two sections and was able to start utilizing this cart for handling the heavy basins. “Our schedule showed us installing an average of 4 basins a day. With the system that Faztek helped us design we have been able to set anywhere between 12 and 15 basins a day” says Superintendent Dave Taft.

Conclusion

“I want to thank everyone at Faztek who had a hand in helping us solve our material handling problem at the Pentagon 9/11 Memorial. Clearly, you have talented designers and engineers that are capable of thinking “outside of the box”. I found that anytime I spoke with a Faztek employee they were both enthusiastic about the project, and eager to help.”

Mobile Gaging System

Overview

This cart was integrated with pivoting components to create a user-friendly mobile gaging system.

Problem/Application

Traditional measuring systems were not ergonomic or user-friendly. There was also a need for mobility to save material handling time by taking the cart to the product.

Solution

Faztek worked with their customer to design and build this mobile gaging system. Strong 1.5” x 3.0” and 3” x 3” T-Slotted aluminum extrusion profiles accounted for the majority of the standard package offered below, along with joining plates to hold it all together securely. Heavy-duty base plates with polyurethane casters were used to provide a smooth cushion on a shop floor.

Conclusion

After building this cart and adding the necessary gaging components, it was apparent the design of this cart provided a perfect solution to their measuring needs. This unit has saved time in measuring products as well as material handling time. This cart provided a perfect solution to their measuring needs. This unit has saved time in measuring products as well as material handling time. This cart is easier to move around because it is 1/3 less weight than traditional steel tubing structures. Strong, sturdy, modular and cost-effective, this unit will provide years of maintenance-free performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications.

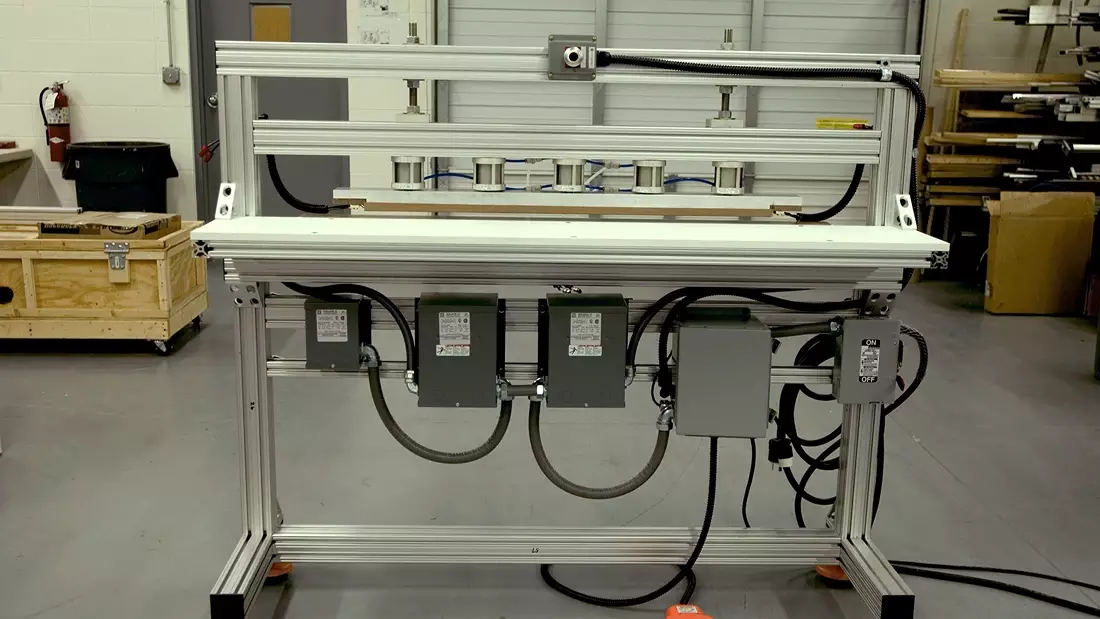

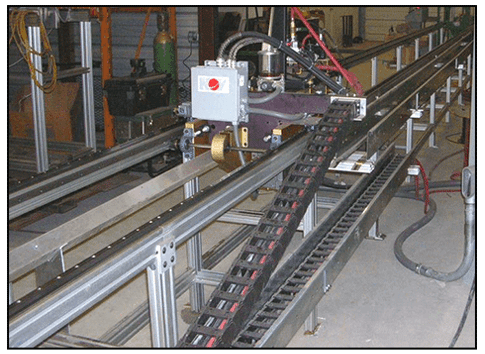

Oilfield Tubing Coater

Overview

This Oilfield Tubing Coater was designed and built to replace traditional coating machines. This apparatus is used to coat the inside of the oilfield tubing with special paints and/or coatings.

Problem/Application

The traditional style machines are slow, outdated drive systems, heavy, and bulky.

Solution

Faztek worked with their customer to design and build a new style of Oilfield Tubing Coater. With Faztek’s Free Design Assistance, we took sketches from their customer to create a working package to build from. Strong 1.5” x 3” T-Slotted aluminum extrusion profiles accounted for the majority of the standard automation package offered below, along with joining plates to hold it together securely. Heavy-duty floor mount base plates with height adjustment for uneven floors were used to provide a secure seat and could also be fastened to the floor if required.

Conclusion

After installation and a quick test run, it was apparent the design of this machine base provided a perfect platform for the Oilfield Tubing Coater. The biggest improvement over old-style coating systems was the updated linear drive system. It provided a more smooth and accurate painting and/or coating. This new system outperformed the old style and has a 50% faster cycle time. The other biggest improvement is from the frame itself with no welding and 1/3 the weight of the previous track system. Strong, sturdy, modular, and cost-effective, these units will provide years of low maintenance performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications.

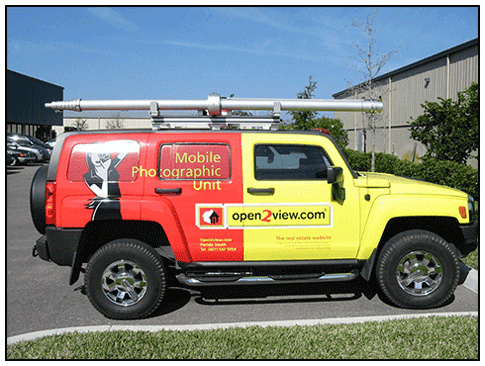

Pneumatic Mast Vehicle Rack

Overview

Hilomast, LLC is a manufacturer of telescopic pneumatic masts for communications and military applications. When one of their customers needed a cost-effective and secure way of mounting equipment to the top of a vehicle, they turned to Faztek’s Design Team for help.

Problem/Application

Unsatisfied with the design and cost of the previous pneumatic mast rack system, a company providing aerial photography needed a better solution to securely mount their equipment. All T-Slot Components would also have to withstand conditions of the outdoor environment.

Solution

After reviewing the specifications of this project, Faztek was able to provide a modular rack capable of supporting the mast and other types of equipment. The clear anodize finish of Faztek’s aluminum t-slot components provided a weather-resistant unit offering years of reliable service. James Brown, Engineering Manager at Hilomast, describes how the modularity of Faztek’s t-slotted extrusions offer several useful advantages: “The t-slots help us to make these adjustments instead of slotting or re-drilling new holes. They are also used to secure air lines and electrical wiring.” Exposed t-slots were covered with plastic snap-in covers to keep the slots clean and provide a finished look. James also commented on the modularity of Faztek’s t-slot materials: “Any future additions or refits are much easier because of bolted (not welded) components that can be removed and modified or replaced.”

Conclusion

“By using the parts and components from Faztek we have saved time, money and improved the looks of our product.”

Pneumatic Tubing Cart

Overview

Faztek has re-designed the traditional pneumatic tubing cart. This cart is constructed from T-Slotted aluminum extrusions, allowing for easy customization and modularity. As an alternative to the other steel units, Faztek’s aluminum frame provides a high-strength, corrosion-resistant cart that will not rust, peel, or fade.

Problem/Application

Customers were looking for a cost-effective, yet sturdy cart to secure their spools of tubing. They needed a lightweight cart to easily move from work area to work area.

Solution

Faztek designed and built a rigid, but lightweight pneumatic tubing cart from T-Slotted aluminum extrusion profiles. This design does not sacrifice quality or strength over the traditional design shown below. A set of 4” swivel and a set of 4” rigid casters were used to provide maximum performance, as well as having two brakes to secure the unit in place.

Conclusion

By switching to the Faztek tubing cart, companies have saved time and money through a lower-cost cart and more options to stay organized. This cart has offered a savings of over 40% compared to the traditional steel cart. Strong, sturdy, modular, and cost-effective, these units will provide years of maintenance-free performance. Best of all, Faztek’s framing system is completely modular, allowing for future modifications. Tool hangers, acrobins, more rails, etc… can be added in a matter of minutes. Great for bin stocking!

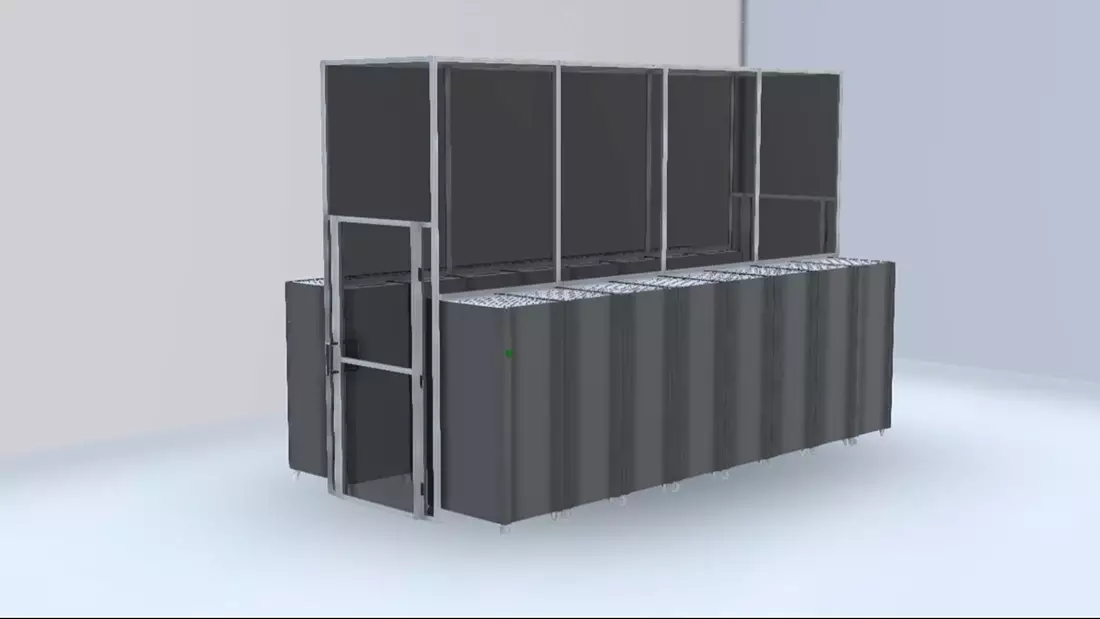

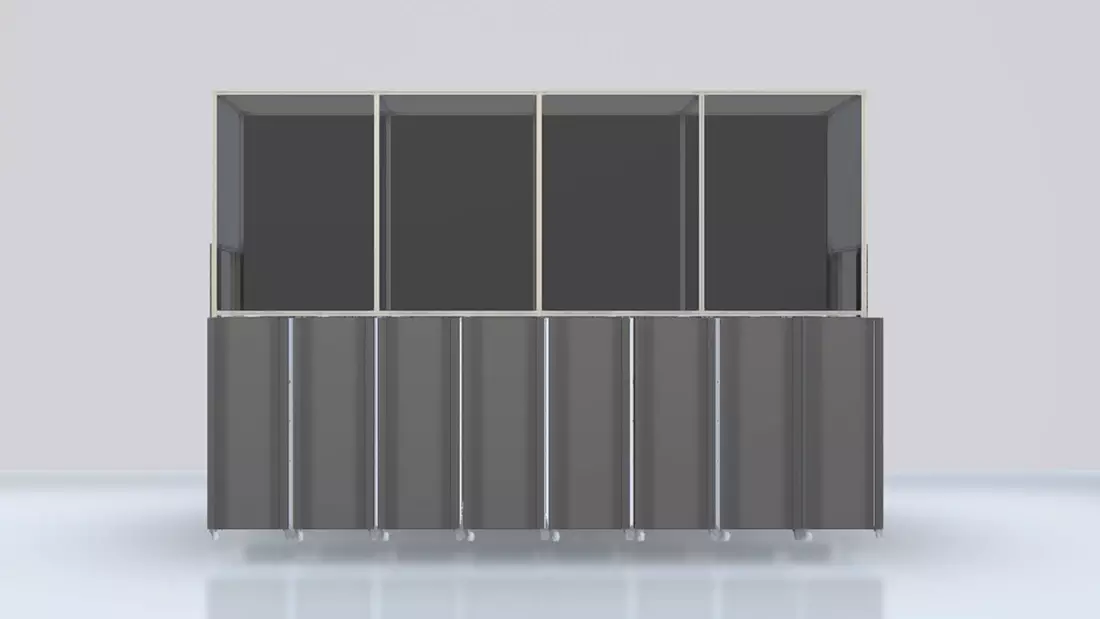

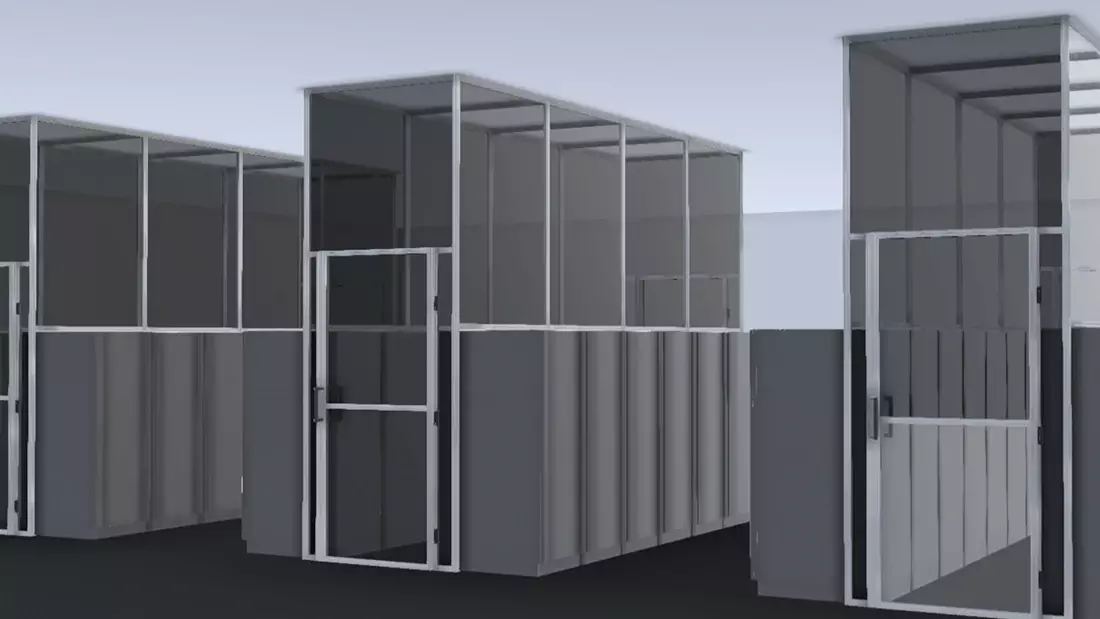

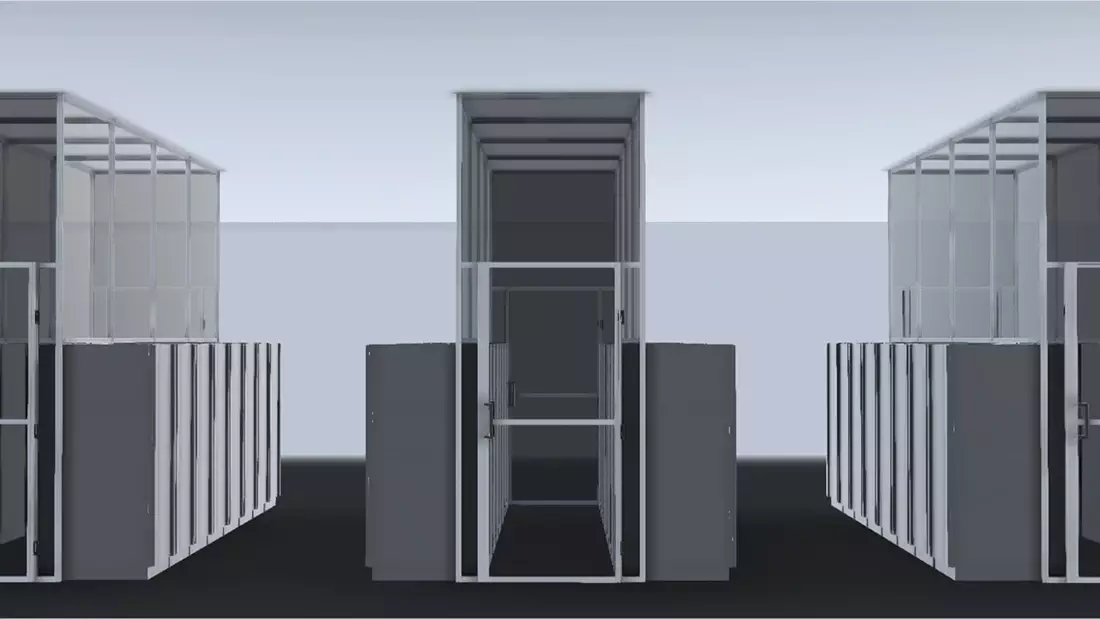

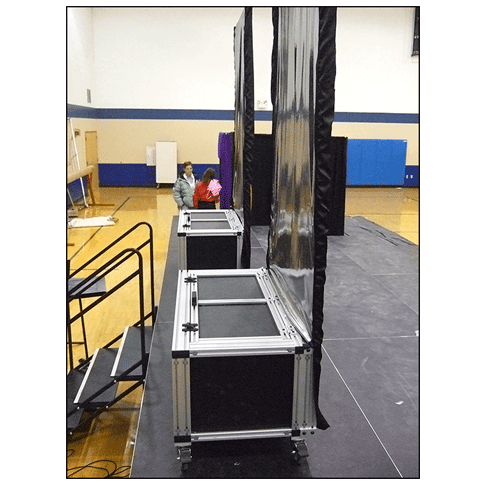

Show Choir Display Set

Overview

Bishop Dwenger is a high school in Fort Wayne, IN was looking for some assistance. When they needed a quick and easy way to set up and break down elaborate sets while looking presentable, they turned to Faztek for help. Backstage appearances are judged as well as performers. Aesthetics, lightweight, and portability are a must!

Problem/Application

Unsatisfied with the design and cost of previous show choir sets, Bishop Dwenger needed a way to easily transport these sets to and from venues. These sets also needed to have flexibility during setup and breakdown.

Solution

After reviewing the specifications of this project, Faztek was able to provide a modular set sturdy enough to hold backdrops but still fold down enough to put back in the travel trailer. The clear anodize finish provided a nice, clean appearance. The lightweight material and large casters make it easy to maneuver around on stage. Bishop Dwenger shows how the modularity of Faztek’s T-Slotted Extrusions offers several useful advantages: “The t-slots help us to make these adjustments easily instead of welding, slotting, or re-drilling new holes. These units can also be disassembled, modified, and turned into other units for Marching Bands, Winter Guard, Winter Drumlines, etc…”

Conclusion

Faztek provided a portable set to store equipment, to display stage screens, and created a quick and efficient way to set up and breakdown for each venue.

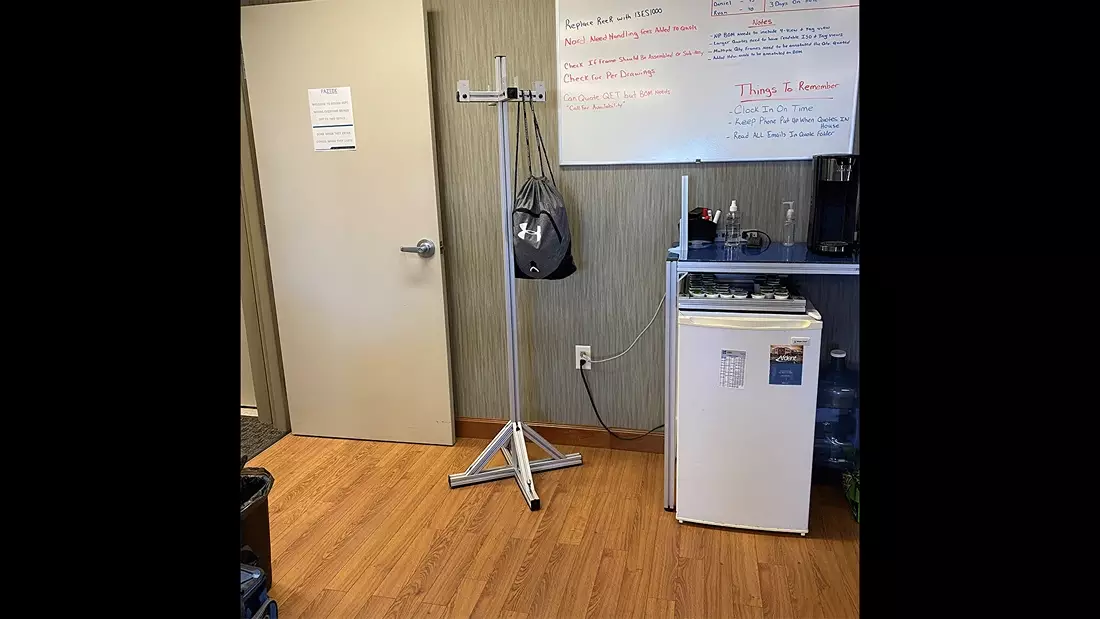

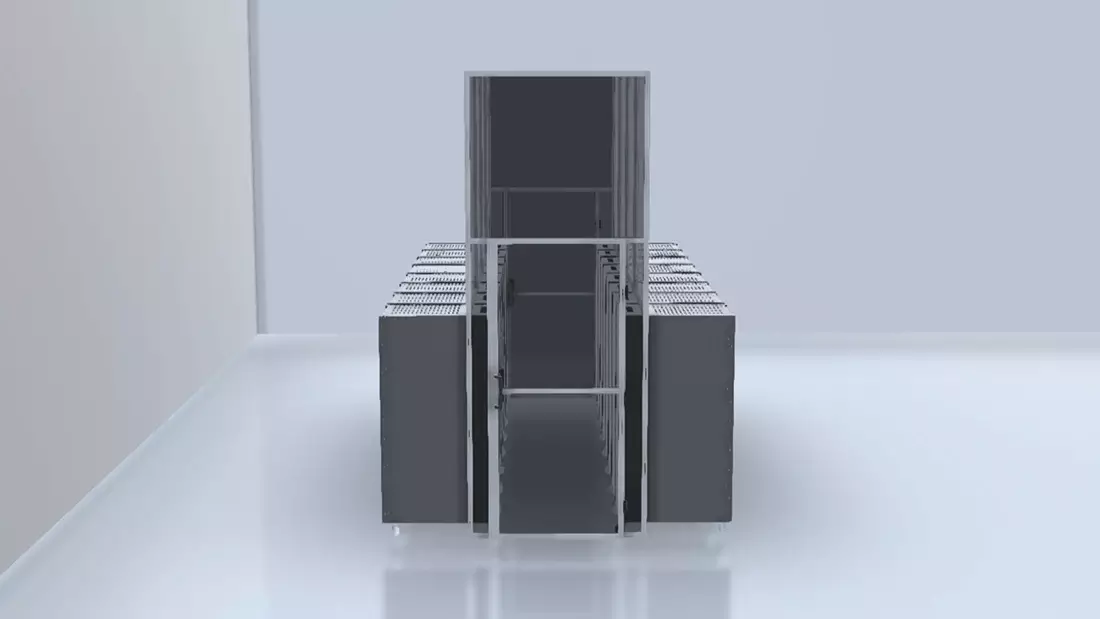

VirusDoc

Two years ago Airbiogenics developed the VirusDoc series. During our design process, we chose to use extruded aluminum framing. No other entity would give us a second glance.

We found Faztek and they were very excited to be part of our product and further development without hesitation. Latricia was our point of contact from the start. From our initial conversation to final development, Bruce, Latricia, Yasser, Christin, Paul, James, Corey, and the rest of the Faztek team all played a critical role in taking our product to the final design and making it a reality.

AirBiogenics is very proud to be working with Faztek on our current products and future developments. Our experience with Faztek has been very prompt, professional, and easy throughout every stage of our product development.

We look forward to a long-lasting partnership with Faztek as our company grows. Mark and Lee have also set time aside to speak with us about our needs, which speaks volumes to us that the owners set time aside to speak with us during their busy schedules.

We have developed a great relationship that will last for years to come. Thank you to the entire Faztek team for all of your help and support!

Miles Smith – Co-owner/Founder

AirBiogenics

Water Carts

I have used Faztek as a supplier since I started in business over 15 years ago. They have always been helpful from assistance with ordering to picking and loading our orders. They understand our needs and do all they can to help.”

Greg Parks

Owner/Mgr of Wheelin’ Water

CALL TODAY

CALL TODAY